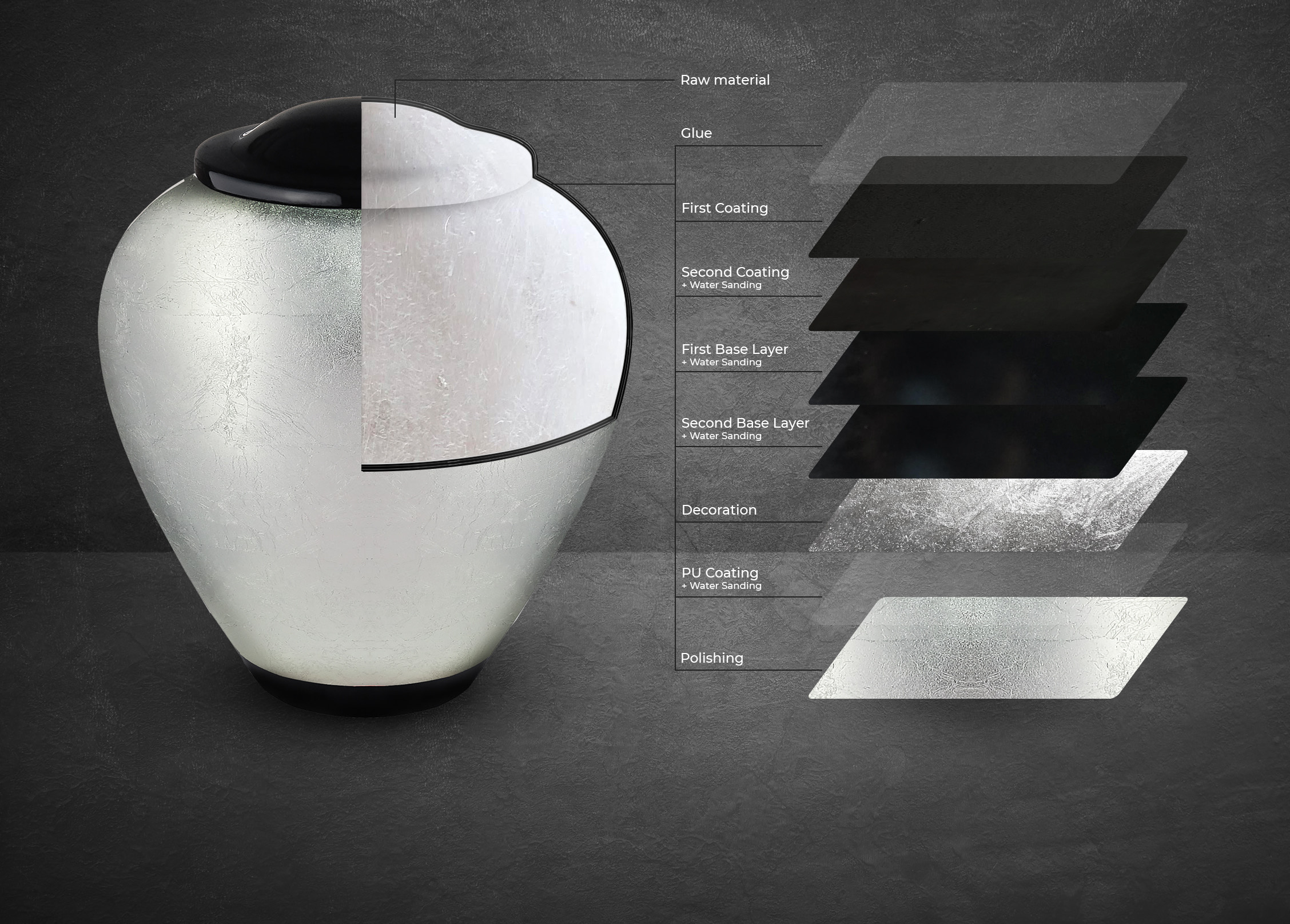

We provide a simplified explanation of the process below:

1.The CORE (raw material)

First, shape is created, either from wood, MDF or FIBERGLASS. Then, the artisans will carefully check the quality of the shape before applying coat of lacquer.

2.Applying Lacquer (1st coating & 2nd coating)

The wood base is first applied specific glue, then applying with a layer of lacquer and then leave it to dry. After dry and hardening, the object is smoothed and polished with sandpaper. This step will be repeated 3-4 times to make sure the base is stable.

3.Sand Paperize (1st base layer & 2nd base layer)

After the mixture is dry, the artisans will cover the product with a layer of natural lacquer. It will be then sanded under the water to make it flat and smooth. This steps will be repeated 3 times as the artisans have to make sure the surface is smooth before apply any design on the surface.

4.Decoration & Design

Eggshell Inlay: The artisan will place little fragments of eggshell onto the surface. Once the eggshell pattern has been laid down, numerous layers of natural lacquer are applied to build up the surface until it is smooth and can be polished.

Mother of Pearl Inlay: The artist will use a coping saw to cut Mother of Pearl into shapes, which will be gathered and inlaid on the surface.

Gold Leaf or Silver Leaf Inlay: The surface will be covered in a natural lacquer then the gold leaf is applied on the surface

Coloring: The artisans will spray 3-4 layers of color in order to achieve the right color richness.

Hand-painted: We have our own experienced artist, who be able to give the painting to life. The Artist will paint directly on the surface. The painted item will be filled with many layers of lacquer and wet sanded until it gets smooth.

5.Applying Glossy or Matt Finish (PU coating)

The Artisans will spray a special glue to achieve either Matte or Glossy surface. This step will be repeated 2 times and it needed to be sanding between each time.

6.Final Sanding

The product will be carefully sanded with a very fine sandpaper to clean all the excessive dust on the surface.

7.Polishing and QC check

In the final step, the artisan will use a chemical to polish the surface to bring out the delicate beauty of the product. Also, our company take quality check extremely careful. Every pieces are checked by our workers to spot any small defections before deliver to our customers’ hands.

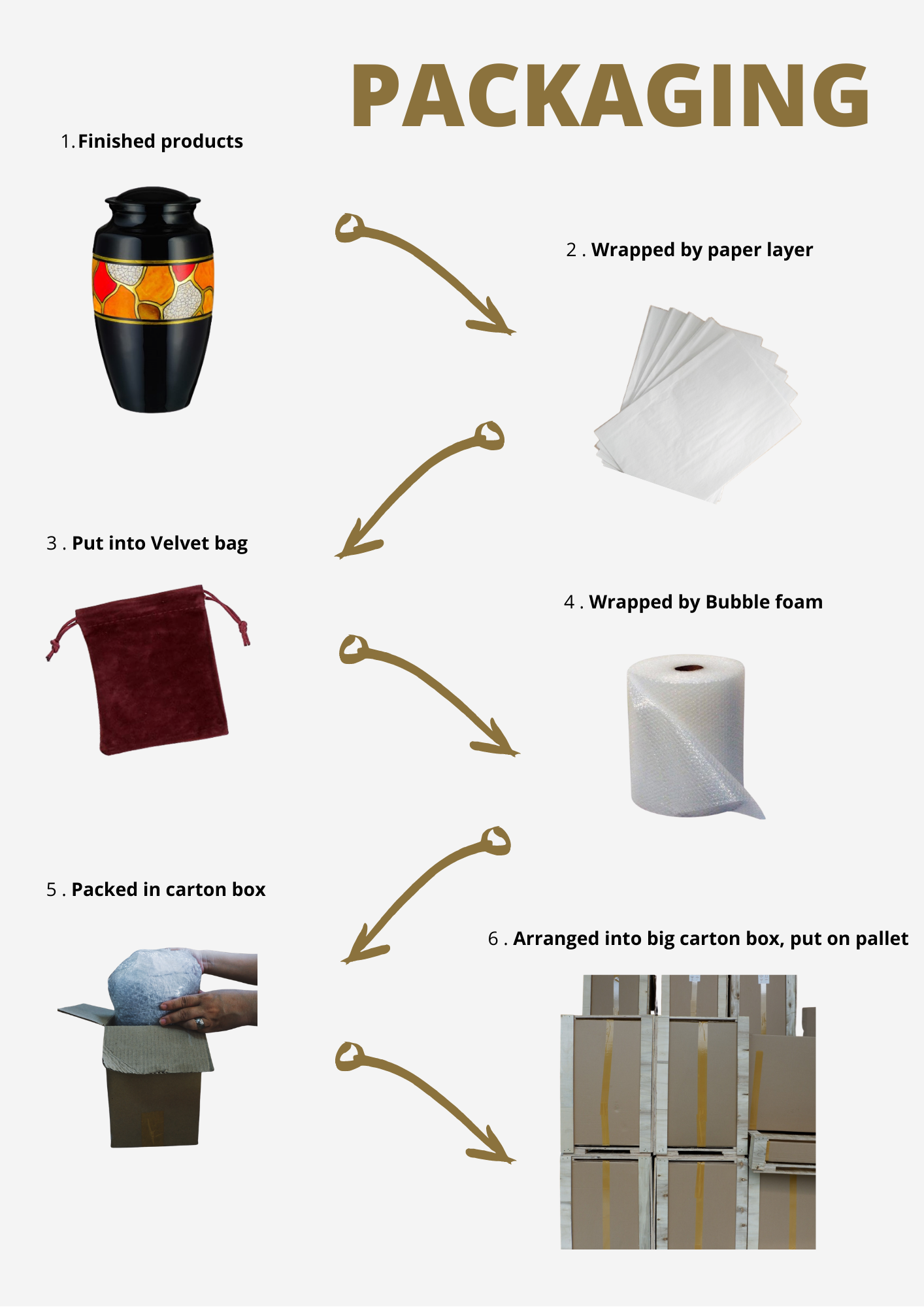

8. Packing

Then, quality products are packaged according to a standard process of as shown in the next diagram.

You can find out more details with many illustrations for each step of the production process in the PDF file at the link below:

If you have any helps or concerns, please kindly no not hesitate email us via: contact@tamvietlacquer.com